GRANSHOT to voestalpine BÖHLER Edelstahl

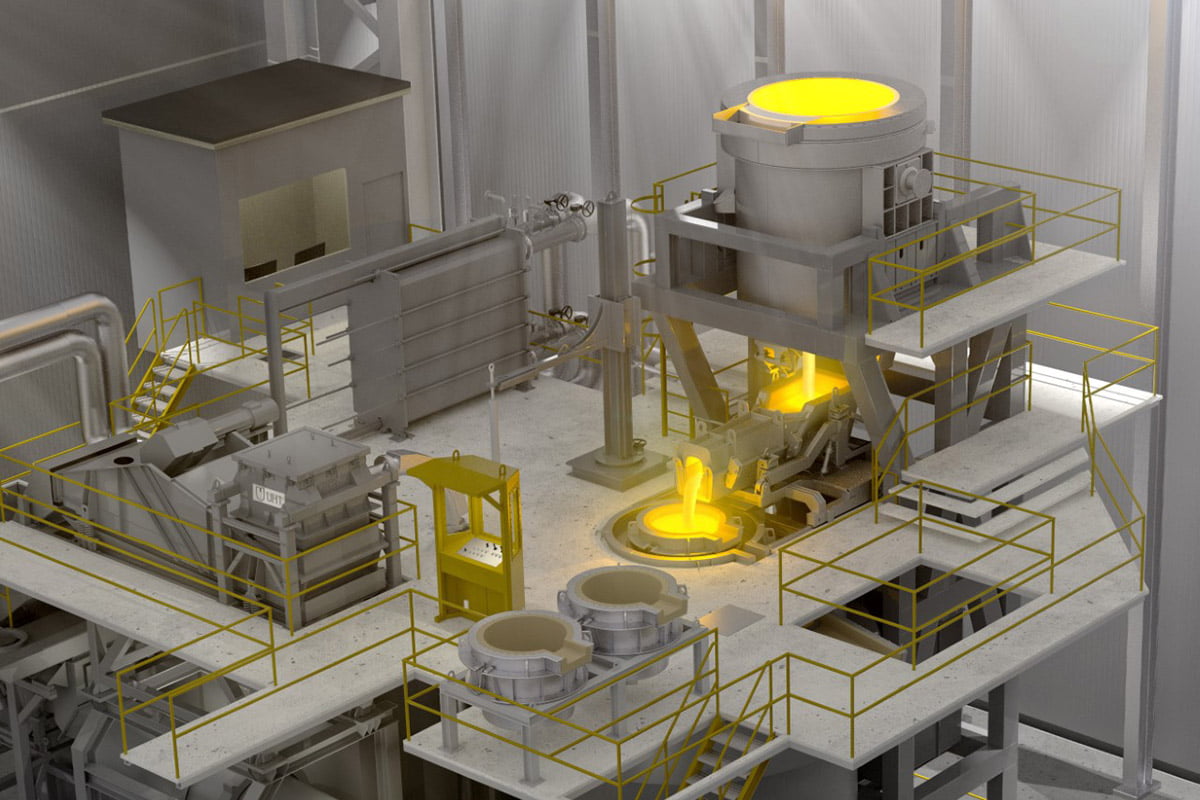

UHT has received an order for a GRANSHOT® metal granulation unit to voestalpine BÖHLER Edelstahl GmbH. The granulation unit will be integrated in voestalpine BÖHLER Edelstahl’s new special steel plant project in Kapfenberg, Austria.

GRANSHOT metal granulation converts liquid metal into granules by rapid solidification in water and the new unit in Kapfenberg will be equipped with UHT’s newly developed Rotating Tundish technology. When the tundish is rotated, the metal distributes through nozzle outlets in a radial direction over the water surface. This new granulation technology is developed to improve the granule properties and is especially suited for steel and ferroalloy granulation. UHT will deliver a complete plant, including process engineering and automation.

The new special steel plant in Kapfenberg will produce around 205,000 tons of high-performance steels, especially for the international aviation and automotive industries as well as for the oil & gas sector.

The GRANSHOT process, developed in-house and with over 50 references, is proven in integrated steelmaking and ferro-alloy industries as an optimum choice for solidifying liquid metal in a secure, environmentally friendly and economical way. Metal granules are homogenous in composition, easy to handle, store and transport.

UHT – Uvån Hagfors Teknologi AB, is a Swedish engineering company and well-established global supplier of metallurgical processes and technologies to the iron, steel, stainless steel and ferroalloy industry. We concentrate our activities to AOD and CLU® converter refining, GRANSHOT® metal granulation and UTCAS® process control system.

GRANSHOT to voestalpine BÖHLER Edelstahl

UHT has received an order for a GRANSHOT® metal granulation unit to voestalpine BÖHLER Edelstahl GmbH. The granulation unit will be integrated in voestalpine BÖHLER Edelstahl’s new special steel plant project in Kapfenberg, Austria.

GRANSHOT metal granulation converts liquid metal into granules by rapid solidification in water and the new unit in Kapfenberg will be equipped with UHT’s newly developed Rotating Tundish technology. When the tundish is rotated, the metal distributes through nozzle outlets in a radial direction over the water surface. This new granulation technology is developed to improve the granule properties and is especially suited for steel and ferroalloy granulation. UHT will deliver a complete plant, including process engineering and automation.

The new special steel plant in Kapfenberg will produce around 205,000 tons of high-performance steels, especially for the international aviation and automotive industries as well as for the oil & gas sector.

The GRANSHOT process, developed in-house and with over 50 references, is proven in integrated steelmaking and ferro-alloy industries as an optimum choice for solidifying liquid metal in a secure, environmentally friendly and economical way. Metal granules are homogenous in composition, easy to handle, store and transport.

UHT – Uvån Hagfors Teknologi AB, is a Swedish engineering company and well-established global supplier of metallurgical processes and technologies to the iron, steel, stainless steel and ferroalloy industry. We concentrate our activities to AOD and CLU® converter refining, GRANSHOT® metal granulation and UTCAS® process control system.

News & stories

Hydraulic converter drive

Unique AOD converter tilting solution Load imbalance and gas injection cause severe converter vibrations during AOD refining which leads to extensive wear on equipment such as the converter drive. [...]

UHT Hackathon 2024

Utveckla ett spel och lär dig mer om programmering! När: 9 mars, kl 9-20 Var: Görsjövägen 3, Hagfors För vem: Gymnasieelever - inga krav på förkunskaper Anmälan: senast 1 mars genom formuläret nedan Obs! [...]

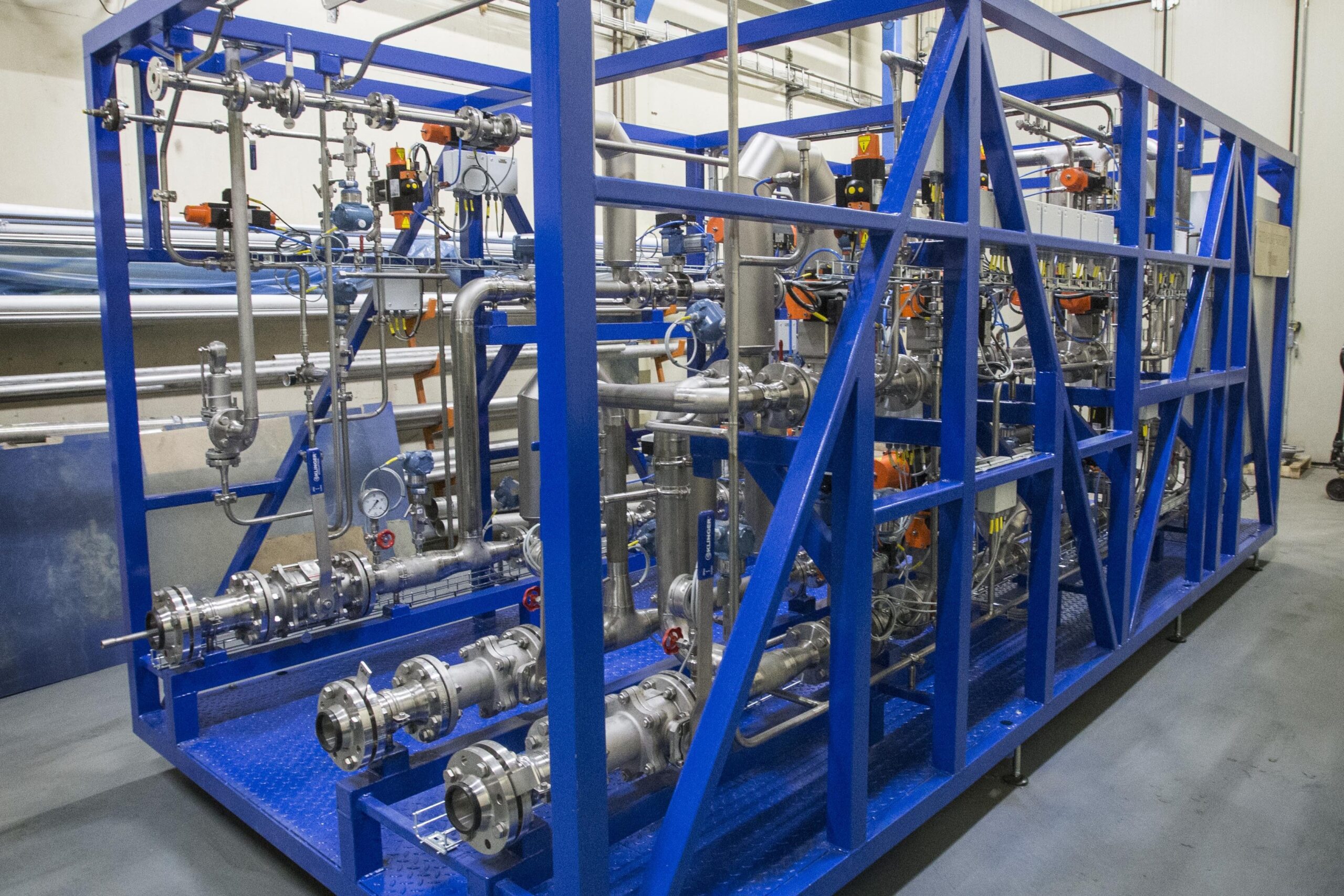

Gas mixing station for AOD converters

Accurate gas distribution UHT's gas mixing station is a versatile solution for distribution of oxygen, argon, nitrogen, and compressed air to the AOD converter. The gas mixing station is engineered, [...]

Talk to an expert

Our mission is to support advanced metal producers to refine their metal processing, increase value, and stay competitive.

Our heritage makes us understand requirements on operations to perform. We focus on stability, throughput and safety, while preparing for the future demands driven by the global transitions.

Fill in the form and book a meeting with one of our experts to discuss your current situation, business objecives and options to obtain a more effeicient metals production.