UHT supplies GRANSHOT FeNi granulation to Horizonte Minerals PLC

UHT has received an order from Horizonte Minerals PLC to supply a GRANSHOT® granulation unit to their new ferronickel refining plant in Conceição do Araguaia, Brazil.

Horizonte’s new mine and refining facility will serve the high demand for ferronickel within the stainless steel industry. The GRANSHOT unit in Araguaia is expected to be commissioned by Q1 2024 and will have a capacity of 90 tonnes per hour.

Today, a large and increasing part of the FeNi on the world market is granulated. With several FeNi granulation installations stretching from South America to the Asia Pacific region, UHT is now the world leading supplier of FeNi granulation technology. The GRANSHOT process converts liquid metal into granules by rapid solidification in water. The granules are homogenous in composition and easy to handle, store, and transport.

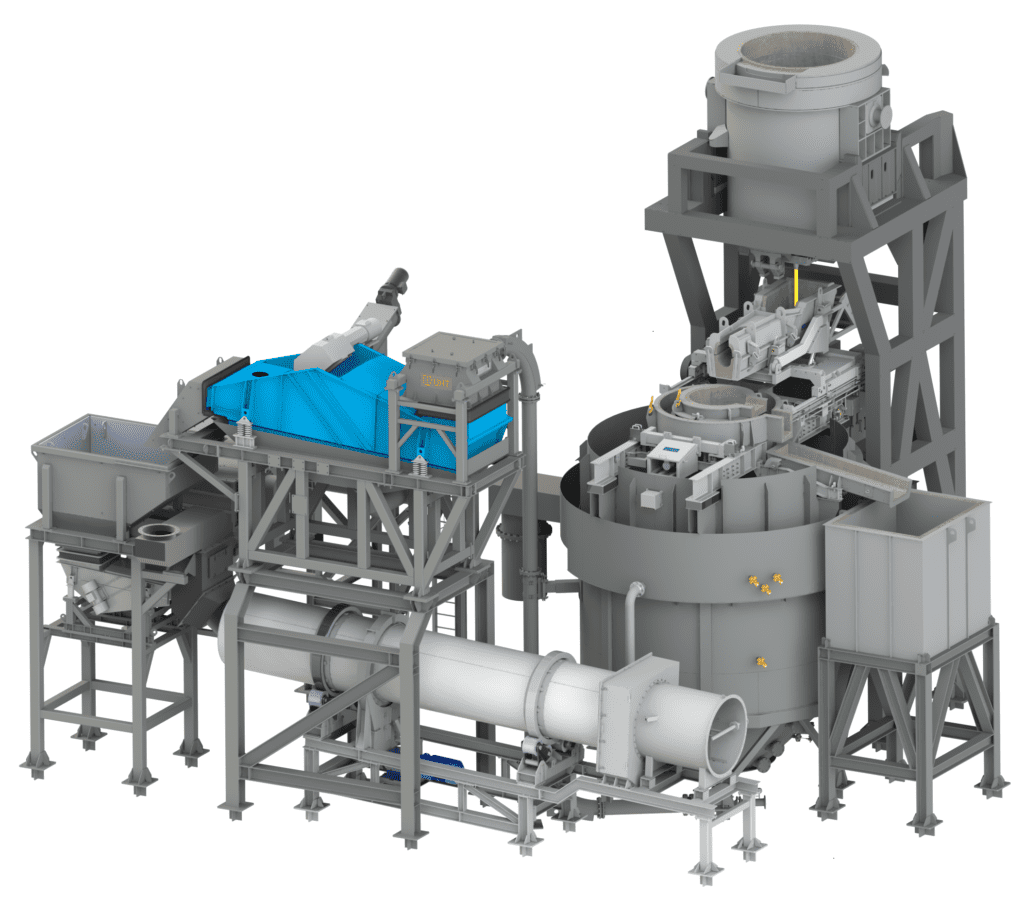

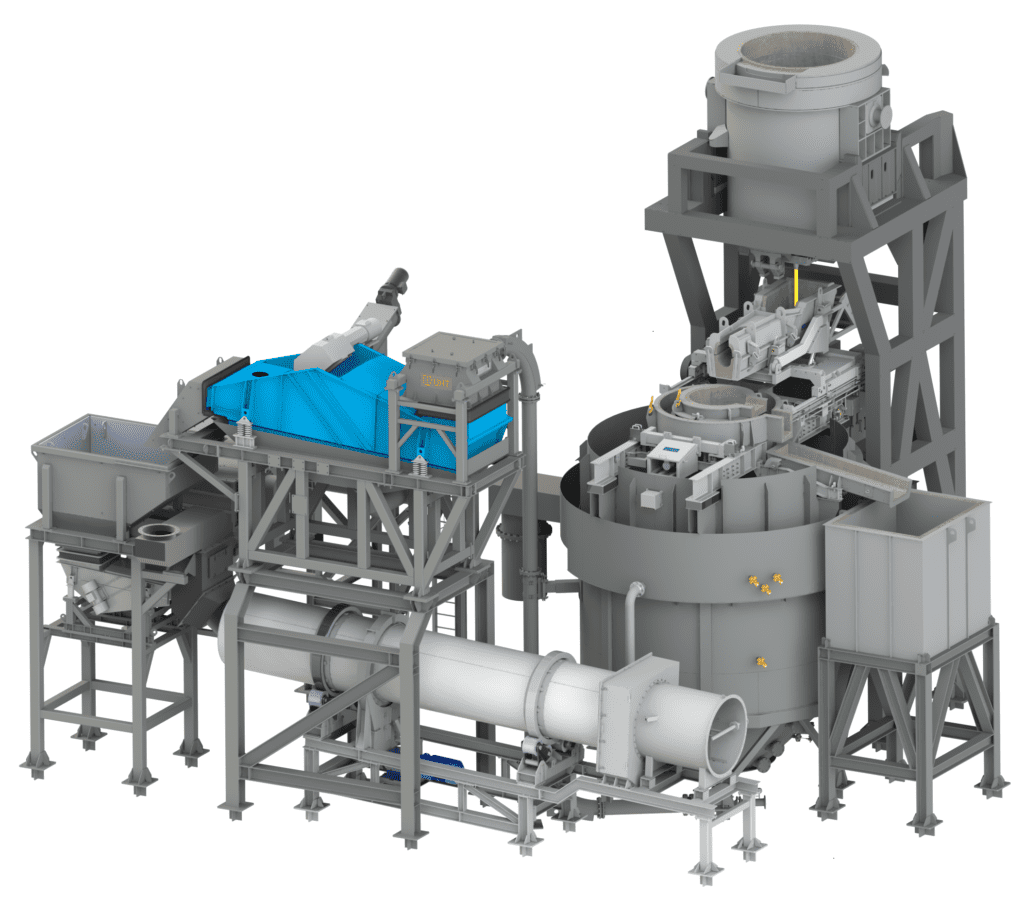

UHT’s long experience in the field and the company’s continuous research and development have resulted in a unique process technology with a rotating tundish specifically designed for the granulation of ferroalloys and steel to improve the granule properties. The molten metal is granulated through the rotating tundish that distributes the metal through nozzle outlets over the water surface into the GRANSHOT reactor tank where the metal is solidified into granules.

The scope of supply for the GRANSHOT unit at Horizonte’s ferronickel plant in Araguaia includes detailed engineering and the supply of key equipment, as well as a Level 1 automation system.

UHT supplies GRANSHOT FeNi granulation to Horizonte Minerals PLC

UHT has received an order from Horizonte Minerals PLC to supply a GRANSHOT® granulation unit to their new ferronickel refining plant in Conceição do Araguaia, Brazil.

Horizonte’s new mine and refining facility will serve the high demand for ferronickel within the stainless steel industry. The GRANSHOT unit in Araguaia is expected to be commissioned by Q1 2024 and will have a capacity of 90 tonnes per hour.

Today, a large and increasing part of the FeNi on the world market is granulated. With several FeNi granulation installations stretching from South America to the Asia Pacific region, UHT is now the world leading supplier of FeNi granulation technology. The GRANSHOT process converts liquid metal into granules by rapid solidification in water. The granules are homogenous in composition and easy to handle, store, and transport.

UHT’s long experience in the field and the company’s continuous research and development have resulted in a unique process technology with a rotating tundish specifically designed for the granulation of ferroalloys and steel to improve the granule properties. The molten metal is granulated through the rotating tundish that distributes the metal through nozzle outlets over the water surface into the GRANSHOT reactor tank where the metal is solidified into granules.

The scope of supply for the GRANSHOT unit at Horizonte’s ferronickel plant in Araguaia includes detailed engineering and the supply of key equipment, as well as a Level 1 automation system.

News & stories

Hagfors Hackathon 2025

Årets tema: Robotics Designa en egen robot, koda och automatisera! Tillsammans med UHT:s erfarna utvecklare får du som är mellan 15-20 år en unik möjlighet att under en hel dag [...]

Welcome Nellie

It is a pleasure to welcome Nellie Andersson Lans to UHT. Nellie is working as Project Engineer and is a valuable team member to our project department contributing [...]

Hydraulic converter drive

Unique AOD converter tilting solution Load imbalance and gas injection cause severe converter vibrations during AOD refining which leads to extensive wear on equipment such as the converter drive. [...]

Talk to an expert

Our mission is to support advanced metal producers to refine their metal processing, increase value, and stay competitive.

Our heritage makes us understand requirements on operations to perform. We focus on stability, throughput and safety, while preparing for the future demands driven by the global transitions.

Fill in the form and book a meeting with one of our experts to discuss your current situation, business objecives and options to obtain a more effeicient metals production.